100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

Wintriss in the News

PRESS RELEASE FEB-2026

Wintriss Controls Group today announced that former General Manager Keith Magnant is serving as the company’s new president, an appointment that became effective Jan. 1, 2026.

FF Journal JAN-2026

Jim Finnerty, Product Manager at Wintriss Controls Group, explains the importance of good communication and careful planning when specifying and implementing press controls.

PRESS RELEASE JAN-2026

Wintriss has acquired all of the assets of ISB, a manufacturer of safety equipment for the metal forming industry.

MODERN METALS DEC/2025

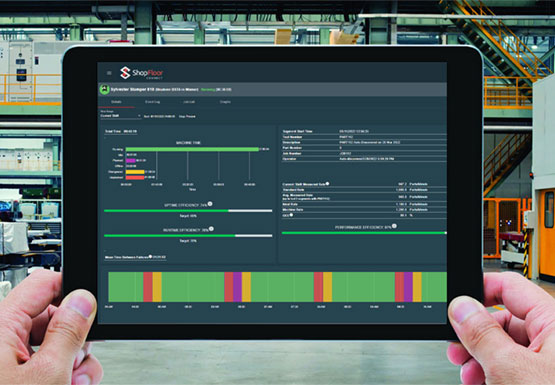

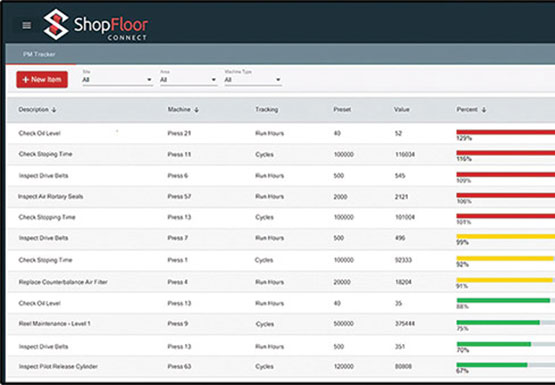

Production tracking software helps a service center unlock the power of metrics to improve efficiency and real-time data collection.

Stamping Productivity Magazine

Whether it's the veterans of the industry or the next generation of operators, the press controls they use need to be intuitive.

MetalForming Magazine

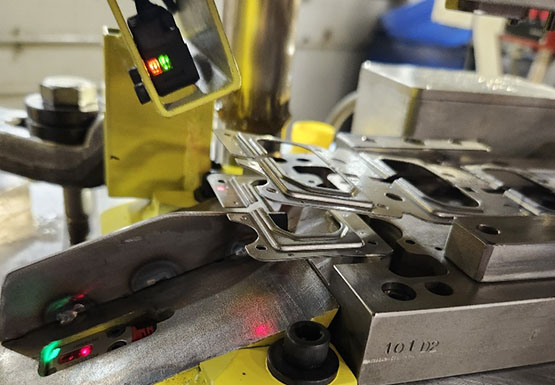

Not every die-protection strategy works the first time, and careful planning and bench testing sometimes aren’t enough to guarantee a trouble free operation.

eBook

Wintriss Controls Group's Jim Finnerty contributed a chapter on Die Protection for Metalfoming Magazine's new eBook.

Press Release

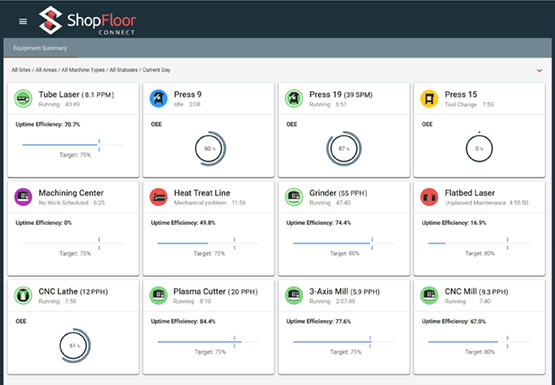

Wintriss Controls Group has added flexible and affordable purchase options for ShopFloorConnect® OEE, Production Tracking, and Data Collection software.

The Fabricator

"To overcome the limitations of manual data collection, production tracking software is available that provides broad visibility into the overall production process and offers an overview of equipment utilization.".

FF Journal

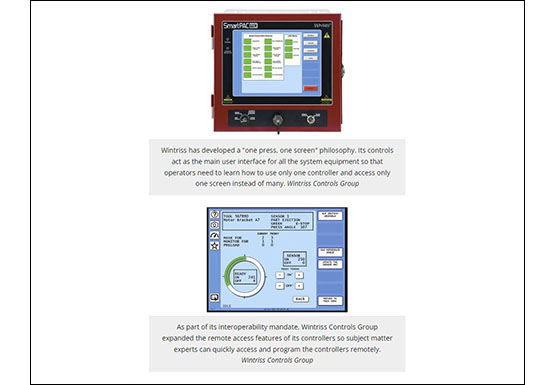

"Wintriss controls can integrate activities such as the feed loop between the feeder and the coil, motor control features or clutch/brake controls".

MetalForming Magazine

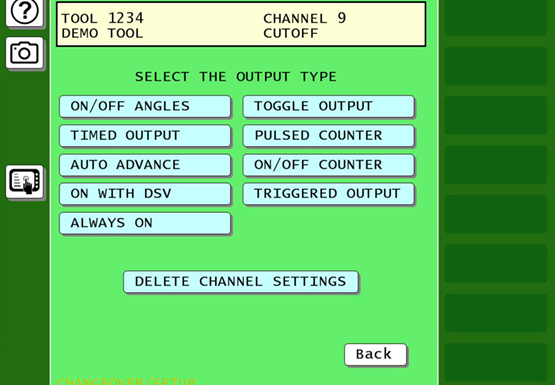

The most important decision metal formers will make when starting a die-protection program is their choice of controller. A misstep here can doom the program before it even starts.

MetalForming Magazine

This article, written by Jim Finnerty, outlines the process of selecting a controller and setting up a die sensor program.

FF Journal

"Growth is the synthesis of change and continuity, and where there is no continuity there is no growth.” It's a distinction that Jim Finnerty, Product Manager for Wintriss Controls LLC understands.

Stamping Journal

This Q&A features Ken Rayden from Bosch Rexroth and Jim Finnerty from Wintriss Controls discussing the current trends in press control technology..

Fab Shop Magazine Direct

Wintriss Controls and ShopFloorConnect help a premier Texas stamping company use data capture and reporting to unearth inefficiencies.

MetalForming Magazine

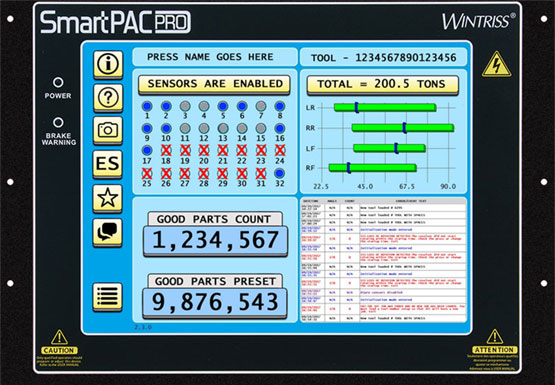

“I like the SmartPAC Pro for many reasons. It's Windows-based, so its quick and easy for our operators to learn and use. The interface is very intuitive. Of course, they also like the touchscreen...”

FF Journal

Combination of controls and software helps manufacturer monitor presses, protect dies and boost throughput...

Metalforming Magazine

"Being able to remotely monitor each press makes it easier to troubleshoot our production, especially during an off-shift where management may not be around."

FAB Shop Magazine Direct

Highly customizable, interactive reports give fabricators the insight they need to make shop floor improvements...

Canadian Fabricating and Welding

What initially started as an afterthought turned out to be a huge benefit for F&P Manufacturing Canada...

Article - FabShop Magazine

This article explores the productivity and efficiency increases that the SmartPAC PRO press controller creates on the pressroom floor...

Today's Medical Devices

Jim Finnerty, Wintriss Controls Product Manager, explains how implementing automated data collection can improve Overall Equipment Effectiveness...

Article - FF Journal

Context is important. Data by itself does not help resolve manufacturers' problems like the bottlenecks or production process missteps that result in unnecessary waste...

Press Release - FF Journal

Building on the proven functionality of the ProCamPAC PLS, the new “PRO” PLS features additional timing options that provide unprecedented flexibility and functionality...

Editorial - FF Journal

The gold standard was formalized prior to 1812 to back the value of paper banknotes. This monetary regime is no longer used, but the phrase became synonymous with a benchmark for quality...

MetalForming Magazine

Jim Finnerty, Product Manager at Wintriss speaks with Brad Kuvin, Editorial Director of MetalForming Magazine about industry trends and new product developments.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved