100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

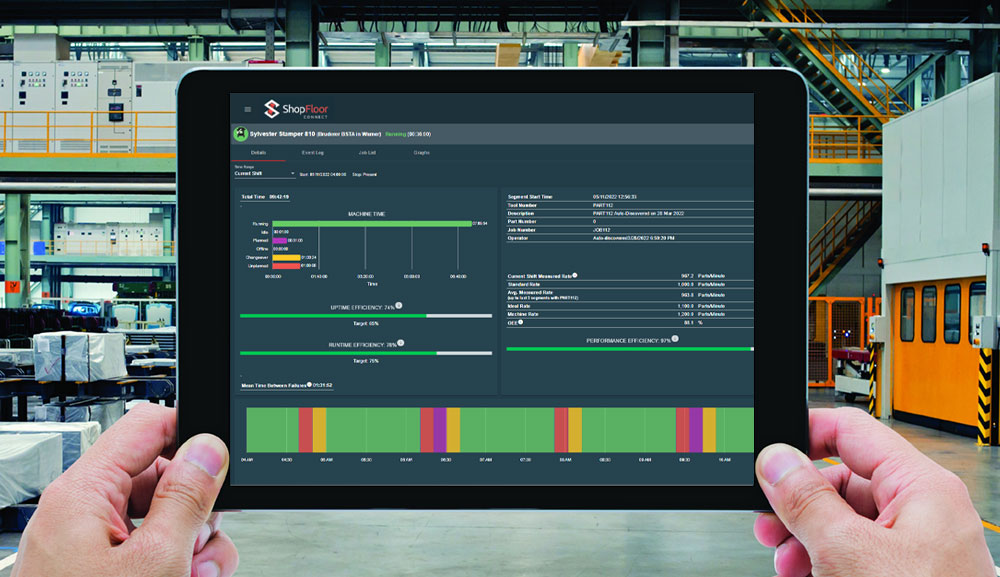

Today's Medical Developments Magazine Highlights ShopFloorConnect

In this new Q & A article, Jim Finnerty, Wintriss Controls Group Product Manager, explains how implementing automated data collection can improve Overall Equipment Effectiveness - critical for medical manufacturers to maintain productive Operations.

/>

/>1. Why is automated data collection important for today's medical manufacturers?

Traceability via documentation is paramount for medical part manufacturers delivering parts to customers. Attempting to manually collect data can be error-prone due to transcription mistakes and operator-to-operator subjectivity. It can also take longer compared with automated data collection methods, which can improve overall equipment effectiveness (OEE) to maintain the most productive operations.

2. What does Wintriss offer for data collection and tracking?

ShopFloorConnect OEE and Data Collection Software collects downtime and production efficiency data from all types of machines, ranging from CNC machines and injection molding machines to lathes and presses in discrete manufacturing, displays the data in real-time, and produces indispensable manufacturing reports, including detailed OEE reports in a variety of formats. The software allows companies to quickly identify and diagnose underperforming machines.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved