100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

SmartPAC PRO - WaveFormPAC

Tonnage Signature Monitor

Advanced through-the-stroke monitor displays and stores tonnage waveform profiles for each tool.

WaveFormPAC monitors the tonnage waveform profiles during each press stroke and stops the press if variations exceed preset limits.

- Verify setups

- Check tool timing

- Monitor snap-through (reverse) load

- Diagnose tooling problems

- Separately monitor clamping and forming forces

- Verify part quality

- Analyze draw speed

- For press speeds up to 250 strokes per minute

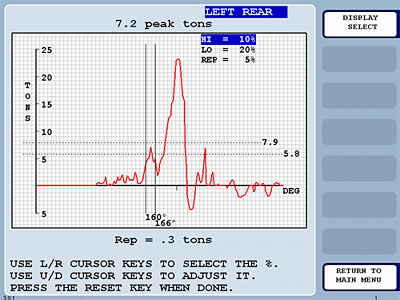

Waveform display showing setpoint windows

Waveform Displays

WaveFormPAC displays the tonnage waveform 'signature' for up to four inputs and total load. This on-screen graph of tonnage versus crankshaft

angle gives diemakers a valuable tool for diagnosing problems and optimizing performance.

Setpoint Limits

WaveFormPAC samples the tonnage and automatically creates setpoint limits for each of the windows and peak loads. WaveFormPAC stops the press when a

variation in the process causes the tonnage to exceed these limits. WaveFormPAC applies four different setpoint types:

- High tonnage limit

- Low tonnage limit

- Repeatability Limit

- Reverse load limit

High and low limits are used to ensure that the peak tonnage and forces in each monitoring window stay within a range that is acceptable for good parts.

The repeatability limit is an additional setpoint that establishes the maximum allowable variation in tonnage from one stroke to the next. Repeatability enables you to detect the very small, abrupt changes in the process that signal problems, at the same time avoiding 'nuisance' stops that can be generated when the high and low limits are set too tight to allow normal variations.

Reverse Load Monitoring WaveFormPAC

simultaneously monitors both forward and reverse loads. Excessive reverse load, also called snap-through or stripping force, can cause major damage to the press.

WaveFormPAC allows you to set a reverse load limit based on machine capacity. When dies with excessive reverse load are reworked by staggering or

adding shear to punches, or by adjusting die clearances, die-makers can use the waveform to ensure that the tooling modifications produce desired results.

Setpoint Windows

Traditional load monitors compare the peak load to preset tonnage limits. These 'peak' monitors can only detect problems that affect the peak tonnage.

For many dies, simply monitoring the peak tonnage is not enough. Blanking dies with punches staggered to reduce snap-through, draw dies, and stretch-forming

WaveFormPAC monitors the tonnage waveform generated during each press stroke and stops the press if variations exceed preset limits dies include critical

forces off bottom that may not exceed the peak tonnage.

WaveFormPAC allows you to view the waveform and then set up to four timing 'windows' with their own setpoint limits to monitor specific forces which, by themselves, do not exceed the peak. Windows are easily set by using the cursor keys to drag indicator lines along the waveform to 'bracket' precise segments you want to track. Whether or not windows are used, WaveFormPAC continually monitors the peak tonnage generated during the press stroke.

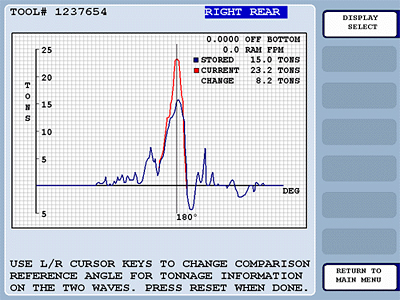

Waveform Storage and Comparison

For every die, WaveFormPAC stores 'benchmark' (theoretically, known 'good') waveforms for each corner of the press and the total load for up. Each time the die is reloaded,

new waveforms can be compared to the stored benchmark waveforms to verify that the setup is accurate.

WaveFormPAC can also temporarily hold an additional waveform for the currently running tool. This feature allows you to compare a waveform from a stroke that exceeds the setpoint limits to both known good waveform and subsequent waveforms to ensure that tooling or material problems have been corrected.

Waveform display showing comparison of current waveform to stored "benchmark" waveform

WaveFormPAC allows you to overlay and compare press-generated waveforms for detailed analysis. A cursor is moved across the comparison screen in precise increments, while a table on the screen shows the tonnage under the cursor for each waveform, the difference in tonnage between the waveform off bottom to help identify specific events in the die.

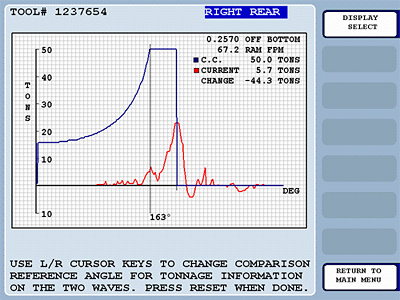

Waveform display showing comparison of current waveform to the press's critical curve

In addition to comparing one press-generated waveform to another, the WaveFormPAC can compare a generated waveform to the press's critical load curve - this allows you to see if the press is exceeding its off bottom load rating.

Distance Off-Bottom and Ram Velocity

WaveFormPAC also displays the ram distance off bottom and the ram velocity in feet-per-minute for every 2/3° of crankshaft rotation for eccentric motion presses.

By comparing the ram distance off bottom to the tonnage, you can quickly identify areas where the tonnage exceeds the press's off-bottom capacity. The ram velocity

display helps you make sure the die is running within the material's drawing speed limit.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved