Creating the Downtime Reason Master List

The first step in configuring ShopFloorConnect's downtime reporting capability is to create a master list of all of the available downtime reasons for your entire installation.

We won't be assigning any reasons to specific machines yet (that's done in another step). The Master List is the repository from which specific reasons will be selected for specific machines.

- Log into the Factory Viewer and click the "Administrator" link in the top-right corner of the page. (You must have administrative

priviledges to access the Administrator).

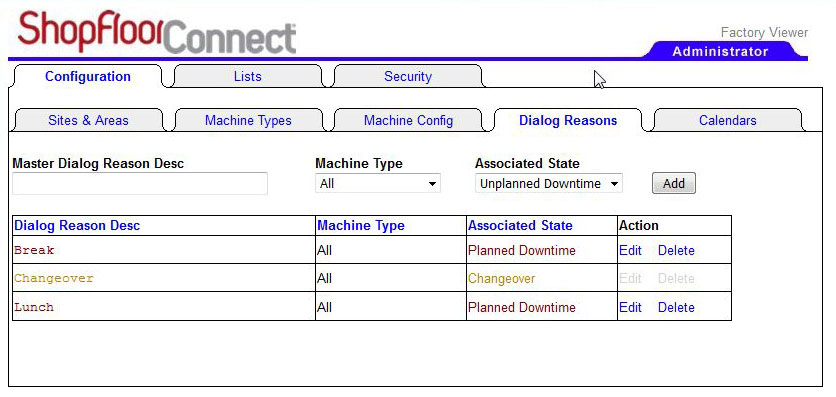

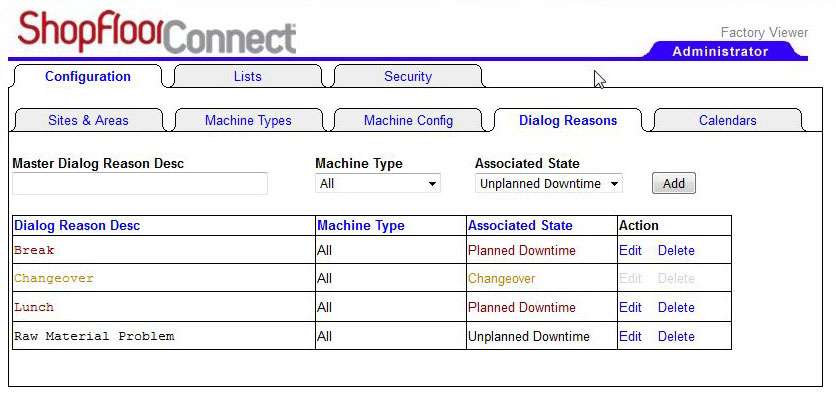

- Select the "Dialog Reasons" Tab to display the Dialog Reasons Master list. When ShopFloorConnect is first installed, the Downtime

Reason master list is empty except for the reasons "Changeover", which is hard-coded and cannot be removed of edited, as well as "Break" and "Lunch"

which are included as samples, and can be changed or deleted.

Figure 1 - Downtime Reason Master List as it appears on a fresh installation

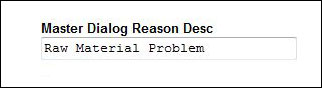

- To add a new reason, type the reason name into the text box labeled "Master Dialog Reason Desc". This name will be the downtime reason as it

will appear in the menu on the machine-mounted control, and on all of ShopFloorConnect's reports and Factory Viewer screens.

Figure 2 - Downtime Reason Name

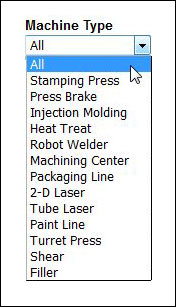

The name should be as descriptive as possible, but if you are creating a reason that will be used on a SmartPAC 1 or 2, it should be 12 characters or less. Reasons that will be used by an SMI or SMI-2 should be limited to 30 characters in length. The name in the example above "Raw Material Problem" would be suitable for an SMI or SMI-2, but for a SmartPAC, it would be better if abbreviated to "Matl Problem" - The "Machine Type" setting determines whether the downtime reason will be available to all machine types, or only a specific machine type. This selection

limits the selections in the pull-down lists for each machine to only the downtime reasons that are applicable to that machine.

Figure 3 - Machine Type Pull-down List

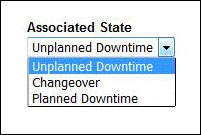

The Machine Type list is a single-select menu. You can only make one selection. So, if a downtime reason is to be accessible to more than one machine type, select "All". - Finally, the "Associated State" selection determines whether the downtime attributed to the reason will be logged as planned downtime, unplanned downtime,

or changeover (setup) time.

Any time logged as "planned" downtime will not reduce the machine efficiency calculations, nor will it reduce the availability portion of the OEE calculation. Planned downtime should be used only for reasons that indicate when the machine was not supposed to be running, such as lunchtime, breaks, and when there is no work available for the machine. the machines

Time logged as "unplanned" downtime will reduce the efficiency percentages as well as the availability percentage in the OEE calculation. Most downtime is unplanned.

Figure 4 - Associated State setting.

Time logged as "changeover" time can be included as either unplanned or planned downtime in your OEE reports, according to a filter that you will set when you configure the report. In addition, the time attributed to changeover is included in the "Average Changeover By Primary" report. Reasons associated to setup-related activity should use "changeover" as the associated state. - When you are finished making the settings, click the "Add" button to insert the new reason into the Master list. Reasons are automatically sorted alphabetically by description.

Figure 5 - Master Dialog Reason list showing the newly created downtime reason (Raw Material Problem)

Important!

The "Edit" and "Delete" buttons allow you to make changes or remove reasons while you're configuring the list. However, you should avoid editing or deleting

any downtime reasons after ShopFloorConnect has begun collecting data, as this will cause "Unknown Reason" to be substituted for the removed reason in all of the

corresponding reports and screen displays. If you want to stop using a downtime reason, leave it in the master list, and remove it from the downtime menus at the machine level.

You cannot duplicate a downtime reason, however you can use a duplicate description with different associated machine states. For example, you could create a reason named "Clean up" associated to planned downtime, as well as another reason named "Clean up" associated to planned downtime. It is not wise to do this, as the machine state is not visible to the machine operators, so there would be no way for the operator to distinguish between "Unplanned Clean up" vs. "Planned Clean up".