ShopFloorConnect Rates (and how to set them)

To explain the different rates used in ShopFloorConnect, let's examine the following example of a production process:

You have a machine that - when it's cranked up to its maximum speed - is capable of producing 300 parts per minute. Let's say you're running a job in the machine that is only possible to run at a speed not exceeding 240 parts per minute (although some operators prefer to run it a little slower). While you run this job, the machine is stopped for an average of 15 minutes per hour while the operator replenishes raw material, checks part dimensions, and clears scrap. In addition, the machine is stopped during the operator's ½ hour lunch, and two 15-minute breaks. Over time, you have come to expect the machine to produce an average of 64,800 parts during an 8 hour shift, or about 135 parts per minute. You have been quoting this job at that rate, but lately you suspect that the machine is taking slightly longer to complete the jobs than it had been in the past.

If you were going to track this machine and job in ShopFloorConnect, you would set the following rates:

The Machine Ideal Rate = 300 parts per minute

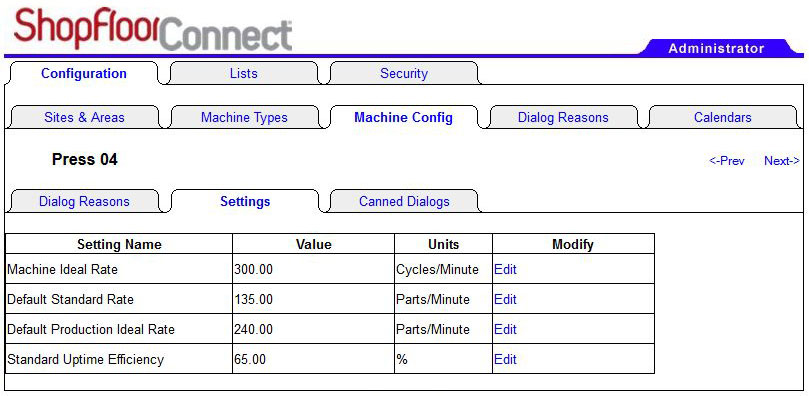

The Machine Ideal Rate is the maximum rate at which the machine is capable of running (in parts/hour or parts/minute). This rate is set once for each machine in the ShopFloorConnect Administrator under Configuration/Machine Config/Machine Name/Settings.

Machine Settings tab in Administrator showing the Machine Ideal Rate setting

Machine Settings tab in Administrator showing the Machine Ideal Rate setting

The Production (or Primary) Ideal rate = 240 parts per minute

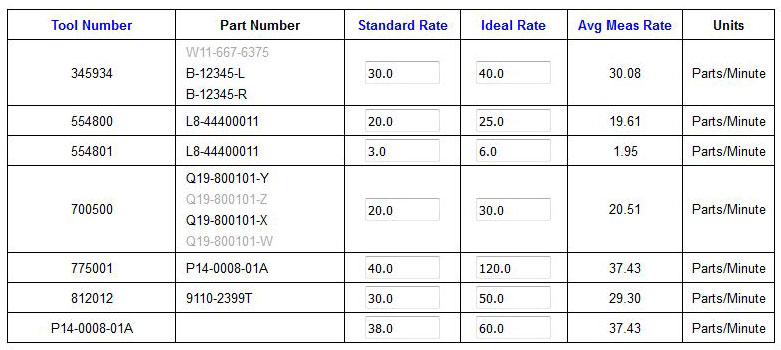

The Production (also known as the "Primary") Ideal Rate is a user-specified value that indicates the fastest possible production rate for each primary item (part or job) that can run in each machine. It differs from the Machine Ideal rate because it is set for each individual part or job. The Production Ideal Rate is set under the "Rates" tab in the machine's equipment detail. This Rates tab has a table with all of the jobs that can run in the machine, and provides places where you can enter and/or edit the Production Ideal Rates for each job. Set this value equal to the maximum possible run rate for the part in the machine.

Keep in mind that this is a theoretical maximum; the machine should not be capable of producing parts at a higher rate than the Production Ideal Rate.The Standard Rate = 135 parts per minute

The Standard Rate is the expected "normal" run rate for a particular primary item (job or part) in a particular machine. Some users refer to this as the "quoted rate". The Standard Rate is the rate at which you would normally expect the machine/primary combination to run. It's the historical, expected AVERAGE number of parts per minute (or per hour) that the machine will run when it runs normally. Like the Production Ideal Rate, the Standard Rate is set under the "Rates" tab in the machine's equipment detail. This Rates tab has a table with all of the jobs that can run in the machine, and provides places where you can enter and/or edit the Standard Rates for each job.

ShopFloorConnect has a provision in the Administrator to allow Production Ideal and Standard rates to be imported in "bulk" from an Excel or comma separated value (.CSV) file.

The Rates Table - Showing the Production Ideal, Standard, and Average Measured Rates for all jobs that

can be run in the machine

The Rates Table - Showing the Production Ideal, Standard, and Average Measured Rates for all jobs that

can be run in the machine

The Average Measured Rate

The Average Measured Rate is a value that is calculated by ShopFloorConnect. It is an average - in parts/minute or parts/hour - of the actual production rate over the last "X" times the job has run in the machine - with "X" being a user-specified number of job runs. ShopFloorConnect uses the Average Measured Rate to calculate job completion times and dates and other calculations.The Average Measured Rate is displayed under the "Rates" tab as a reference for users to compare to their Standard Rates -the idea being that the Standard Rate should reflect the actual production rate. By displaying both, users can see which Standard rates need to be upgraded when productivity improvement efforts yield positive results.