Fab Shop Magazine Direct

Wintriss Controls and ShopFloorConnect help a premier Texas stamping company use data capture and reporting to unearth inefficiencies.

Editorial - FF Journal

The gold standard was formalized prior to 1812 to back the value of paper banknotes. This monetary regime is no longer used, but the phrase became synonymous with a benchmark for quality...

Manufacturing Today

Manufacturing Today profiles Chicago-area manufacturer and long-time ShopFloorConnect power user Wiegel Tool Works.

FF Journal

Combination of controls and software helps manufacturer monitor presses, protect dies and boost throughput...

Canadian Fabricating and Welding

What initially started as an afterthought turned out to be a huge benefit for F&P Manufacturing Canada...

FAB Shop Magazine Direct

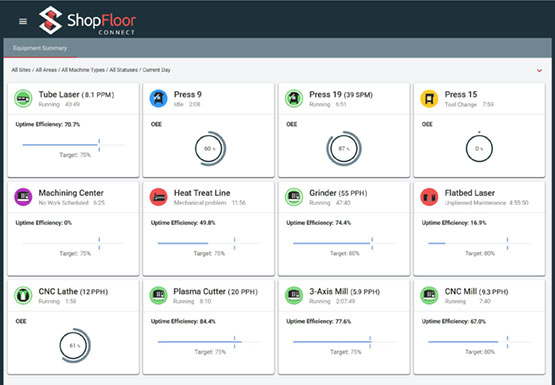

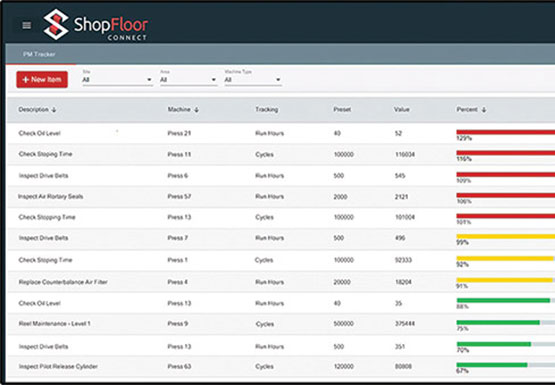

Highly customizable, interactive reports give fabricators the insight they need to make shop floor improvements...

Todays Medical Devices

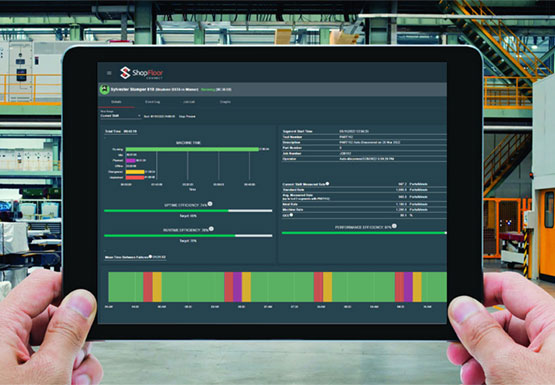

Jim Finnerty, Wintriss Controls Product Manager, explains how implementing automated data collection can improve Overall Equipment Effectiveness...

Article - FF Journal

Context is important. Data by itself does not help resolve manufacturers’ problems like the bottlenecks or production process missteps that result in unnecessary waste...