100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

SmartPAC PRO - ProPAC Slug Detection Package

Monitor stripper position at BDC with this easy-to-use package

Chances are good that if your dies do any piercing, you’ve had trouble with pulled slugs. At best, a pulled slug will negatively affect part quality; at worst, it can do serious damage to the die. Wintriss has developed a package for SmartPAC and SmartPAC PRO with ProPAC that enables you to detect pulled slugs (and other malfunctions) before the die is damaged. Low-profile analog proximity sensors are used to measure the height of the stripper at bottom dead center.

The Wintriss package consists of:

- 8-input ProPAC Module

- ProPAC Die Plug (PDP)

- 10' PDP Cable

- 4 Sensors and Connectors

For a limited time, Wintriss is offering this package with special pricing. Other configurations and wiring accessories are also available.

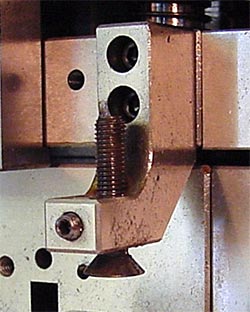

Low Profile Analog Proximity Sensor

Photo courtesy of Ramcel Engineering, Northbrook, IL

The Sensors

The system uses low profile analog proximity sensors. These sensors output a voltage that is proportional to

the sensor-to-target distance. As the target (in this case the stripper plate) moves closer to the sensor, the

sensor's output voltage goes up. The sensors have a detecting range of 1.0 to 4.0 mm and an output of 0-10 volts.

The sensors have a repeatability of 40 µm (0.0008”), allowing them to detect even the smallest pulled slugs or slivers on top of the strip. In one application, ProPAC is able to detect when the stripper is too high by 0.0005" at 900 SPM!

Easy to Install

The sensor’s low profile–the unit is only 8 mm (0.315”) high–and long range give you a great deal of

flexibility when choosing a mounting location.

If the sensor cannot be placed under the stripper itself, simply install an extension “target” on the stripper so that the sensor can be mounted outside of the die blocks (see the photo on the right).

The sensor’s long measuring range enables it to detect a metal object that is anywhere from 1.0 to 4.0 mm (0.040” to 0.160”) away from the sensor.

Adjustable Extension Target for Sensor

The exact placement of the sensor is not critical. The sensor installation is acceptable as long as the stripper position at BDC is near the middle of the sensor's range. Since the sensor has a 3 mm range (0.120"), you can practically position it "by eye".

Easy to Set Up

The ProPAC uses automatic setpoints to monitor the sensors. With a single keystroke, the operator tells

the SmartPAC to automatically create setpoint limits for the sensors when the die is first loaded.

This eliminates the need to readjust the sensors when work is done on the die between job runs.

The ProPAC samples the stripper height for a preset number of strokes (the "Sample Period") and sets the high, low, and repeatability limits based on user programmed percentages.

How it Works

Sensors are installed on the lower die shoe under the corners of the stripper plate. The sensors measure the height of the stripper at bottom dead center.

When the die is running normally, the stripper height at bottom will fall within the sensors' setpoint limits (see diagram below).

Normal Operation - Sensor signals within setpoint limits

If a pulled slug (or any other foreign object) lands on top of the strip, it will prevent the stripper plate from coming all the way down at bottom. The sensors will detect that the stripper height is outside of the setpoint limits, and the ProPAC will stop the press (see diagram below).

Pulled Slug - Sensor signal is outside of the setpoint limits. Press stops

For maximum effectiveness, we recommend that you use four sensors, one under each corner of the stripper plate.

The Wintriss ProPAC has 8 or (optionally 16 or 32) inputs. Unlike other systems that can only be used to monitor shutheight/stripper position, ProPAC's other inputs can be used for a variety of in-die measurement and process monitoring applications such as form angle and part measurement, bearing temperature, and motor current monitoring.

Click here to download a printable version of this page in Microsoft Word format.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved